How to choose non-standard fixture tools

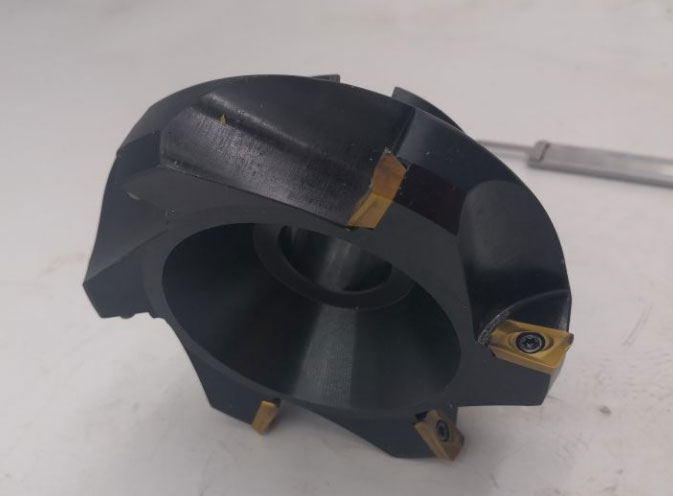

2022-05-27 13:15Non standard tools refer to the tools that are most practical for complete or partial cutting of parts. They are based on the verified scale point of view, such as existing blades, clamping devices, tool handles and interfaces; It is probably a special tool handle equipped with multiple scale blades, which can be used as two or more scale tools; It is also probably an indexable blade made of special cemented carbide material and / or groove shape, which has the largest utilization and can probably provide longer and more stable non-standard tool life. Related to non-standard tools also include incomplete scale. As an alternative to standard tools, it has the characteristics of small defects. Buy high-precision non-standard cutting tools and recognize that tihao machinery is based on high-precision tool handle, collet, rotary center and non-standard cutting tools.

When it is necessary to process more and more huge parts, the various characteristics of parts require the acceptance of special non-standard tool schemes. This is also applicable to parts with simple processing, because the non-standard tool scheme can eliminate the production bottleneck encountered. There are many places to take non-standard tools as the best scheme, including most of the processing categories, materials and industry examples, and the most is the combined tool scheme that can represent most of the non-standard tools. These schemes are usually based on various combinations of scale blade, tool clamp, tool interface, drilling groove, anti vibration system or tool holder clamping device. Pure non-standard tools with unique performance account for nearly one quarter of the total number of non-standard tools, while non-standard tools with similar scale tools account for three quarters. The processing category is deep hole processing and the processing of parts made of composite materials. It is considered to be an important place to use non-standard tools. This kind of composite materials are mainly carbon fiber reinforced plastics (CFRP) and materials that support the composite materials through metal stacking. To the production bottleneck. There are many places to take non-standard tools as the best scheme, including most of the processing categories, materials and industry examples, and the most is the combined tool scheme that can represent most of the non-standard tools. These schemes are usually based on various combinations of scale blade, tool clamp, tool interface, drilling groove, anti vibration system or tool holder clamping device. Pure non-standard tools with unique performance account for nearly one quarter of the total number of non-standard tools, while non-standard tools with similar scale tools account for three quarters. The processing category is deep hole processing and the processing of parts made of composite materials. It is considered to be an important place to use non-standard tools. This kind of composite materials are mainly carbon fiber reinforced plastics (CFRP) and materials that support the composite materials through metal stacking.